GS740 4 stroke

Introduced in 1977, the GS750 (B) was Suzuki's first large capacity four stroke and they managed to carryover a few parts from the GT750 including the much of the transmission. There are a few changes but all the gears from second to fifth are the same number of teeth as a late model GT750. The one that's different is First gear pair which consists of a drive gear ground into the input shaft and a large diameter driven gear.

First gear was raised and that brought it closer to second, which all but eliminated the nasty jump from first to second on a GT. It kept the tighter second and third that were introduced towards the end of the 76 GT750 A production and uses the lower top gear which came in on the L model. Overall it's a better set of ratios than any GT transmission, and represents a huge improvement from early GT750 gear ratios. And that's why we are interested in this possible transplant.

Another possibility is the transmission from a 1980 on 16 valve GSX models which is very similar. The 81 on 16 valve motors had some revisions to the transmission that are worth talking about. The input shaft is longer than an 8 valve GS750 and the dog design was finally changed on 3rd gear.

A GS/GSX1100 16 valve had a few additional improvements including a higher first gear and needle roller bearings in 1st gear plus the introduction ov wave washer to take up slack in the shafts.

Comparisons

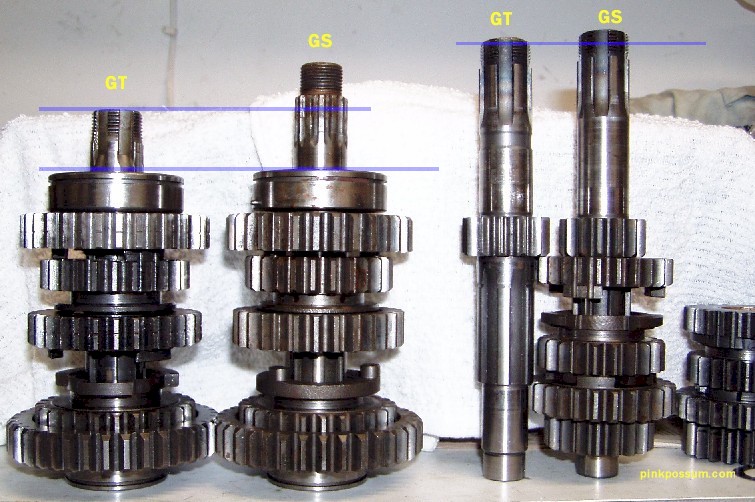

Shafts

The input shaft (on the right) is the same width between bearings and drops straight in on the half moon clips but is longer where the clutch fits. It, and many later 600, 750 and 1000 GSX and GSXRs share the same spline pattern and shaft diameters.

|

Input Shaft

Bad news is that the intake shaft is also longer and the nose is different. Remember the lubrication story? Well that the first difference. The end of the GS shaft is not machined to take an oil seal and it's hardened.

The second difference is that the shaft is 6 mm longer where the clutch drum fits and that makes things a little more tricky.

The solution so far is to machine approximately 4-5mm off the threads, machine a recess to take the GT oil seal and modify the clutch drum to fit closer.

|

Output Shaft

The output shaft is longer overall, and has a different spline arrangement which is a better design that the GT and uses sprockets which are common to other bikes, so that's a second bonus with the GS shafts. The GS and 16 valve GSX750 output shafts are longer than the GT and that moves the sprocket out - great for fat tire conversions.

For comparison the overall lengths are: GT -170mm, GS - 180mm, and GSX - 191mm The real issue though is that the GS and GSX output shafts are also wider between the bearings by 1.6mm and that increases the degree of difficulty somewhat. In the photo at the top, it is just possible to see that the bearing on the GS shaft sits marginally taller on the shaft.

With all the gears and circlips removed, the measurements between circlip grooves were taken and they confirmed that the difference is in the area that Forth gear sits on the shaft.

With the GSX shaft placed in a set of GT crankcases, that 1.6mm mismatch is more obvious.

The solution depends upon the desired outcome. A GT output shaft can be used if a rear tire of less than 140mm is used with no other changes - assuming that the slightly larger diameter GT first gear will work with the GS input gear, and that after all is the one gear we must get out of this swap.

It is also possible to machine the flange against which the output bearing rests, but ensure that there is sufficient material there to avoid any possible lateral movement or failure in use. That will allow the bearing to be slid back into place and be retained correctly by the half moon clip. Do not be tempted to leave out the clip or to botch the machining. The consequences of error can be serious.

That leaves one last little issue to deal with, and that's the reason that the GSX shaft is wider. It is wider because both 4th and second gears are different. Both gears are wider and the dogs on 4th that slide into 2nd gear are longer. In a set of GT cases, 4th gear is too close to 2nd and it is possible that it will snag and engage while another gear is also engaged. That will instantly lock the rear wheel and may cause a crash. That would be decidedly sub-optimal.

The fix (if it is necessary) is to grind the end so of the dogs to allow at least 0.50mm clearance and there must be no evidence of the two gears rubbing or clicking against each other.

Gear change

The GSX gear change drum is longer than a GT, and the sprocket side end is much larger, but it apparently has the same cam profile. The two selector forks for the rear shaft appear to be identical, but the single one for the front (input) shaft is different. So it looks like we can keep the GT shift drum and selector forks too.

|

Gears

Let's go back to the differences in that first gear set which is the whole point of this conversion after all. The ratio is 14/36 on a GS versus 13/37 on a GT, and that could be a problem. On a GT750 the CCI oil pump drive gear engages with the first gear on the output shaft, so any drastic change and all bets are off.

Good news is that although the driven gears have different numbers of teeth, there is only 0.4mm difference in diameters of the gears we measured.. That's a gear cutting trick. So far so good. The same is not true of the gear it meshes with. That gear is machined into the shaft itself. It isn't pressed on or welded or splined. It's part of the shaft and that's why this conversion is a couple of steps harder than it might have been.

It looks like all of the removable gears on a GS shaft can be used on a GT shaft although the dog designs are different on a couple of gears. Some of the gears are wider which makes then heavier than they need to be, but that's OK.. Likewise, GT gears fit onto GS shafts.

If using a GT output shaft and GT first gear with GS input shaft, check for sufficient backlash in the first gear set.

WARNING

Modifiying transmissions requires machining shafts and in some cases the bearings also have to be modified. It is the responsibility of the owner and engine builder to ensure that gears are shimmed to provide correct clearances. Failure to correctly shim the transmission can result in the simultaneous engagement of two gears which can cause catastrophic damage and could cause the rider to lose control of the vehicle.

Clutch

A GT750 clutch is an unusual design and has many parts that cannot be swapped out because if you do, the shaft and clutch cannot be fitted without splitting the cases. The longer GS shaft exacerbates that situation and moves the clutch pressure plate too close to the outer cover and lift mechanism. That could be cured by adding a 6mm spacer between the crankcases and the clutch cover.

Unfortunately, moving the clutch hub outwards to match the GS shaft also means that it becomes impossible to use the stock number of clutch plates.

An easy solution would be to commission Ellis Moore at MPE in the UK to machine up a new input shaft with GS sized 14 tooth gear on a GT shaft.

An alternative might be to grind off the old gear and press on and weld a new gear.

The third possibility is to modify the GS shaft to move the clutch inwards to the same position as on a GT. As mentioned above, the shaft can be shortened and machined to take a GT oil seal. The clutch inner hub can also be machined to fit slightly deeper onto the shaft.